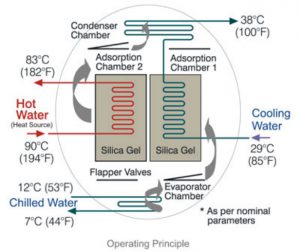

Working principle

The principle of Adsorption works with the interaction of gases and solids. With adsorption chilling, the molecular interaction between the solid and the gas allow the gas to be adsorbed into the solid. The Adsorption chamber of the chiller is filled with solid material, silica gel, eliminating the need for moving parts and eliminating the noise associated with those moving parts. The silica gel creates an extremely low humidity condition that causes the water refrigerant to evaporate at a low temperature.

As the water evaporates in the evaporator, it cools the chilled water. The Adsorption chiller has four chambers; an evaporator, a condenser and two Adsorption chambers. All four chambers are operated at nearly a full vacuum.

Comparison with VAM

|

Factors

|

Adsorption Chillers

|

Absorption Chillers

|

|

Life Expectancy

|

Greater than 25 Years

|

7 to 9 Years

|

|

Maintenance

|

Negligible Maintenance

|

Require High Maintenance

|

|

egeneration Temperature (Hot Water)

|

Down to 50°C (122°F)

|

Shuts down at 82°C (180°F), Needs Back-up Heater

|

|

Desiccant Use

|

Silica Gel (Inert)

|

Lithium Bromide (Highly Corrosive)

|

|

Replacement Requirements (Periodic Maintenance)

|

Not Required

|

Heat Exchangers, Boilers, Absorbent Replacement Required

|

Advantages

Unbeatable Advantages

- Long product life ( >25 yrs. ).

- Low maintenance.

- Regeneration temperature as low as 50°C.

- ‘Green’ refrigerant ( water ).

- Low electric consumption ( one-tenth the conventional system ).

- No noise and vibration.

Additional Advantages

- Start-up time 5 to 7 minutes compared to 15 minutes for Absorption.

- Chilled water output 5°C – 10°C ( 40°- 55°F ).

- No crystallization, corrosion, hazardous leaks, or chemical disposal issues.

- No vibration or noise. Simple and continuous operations.

- COP of 0.55 ( Coefficient of Performance ).

- Versatile operation – Can be used for a wide range of industrial and commercial applications.